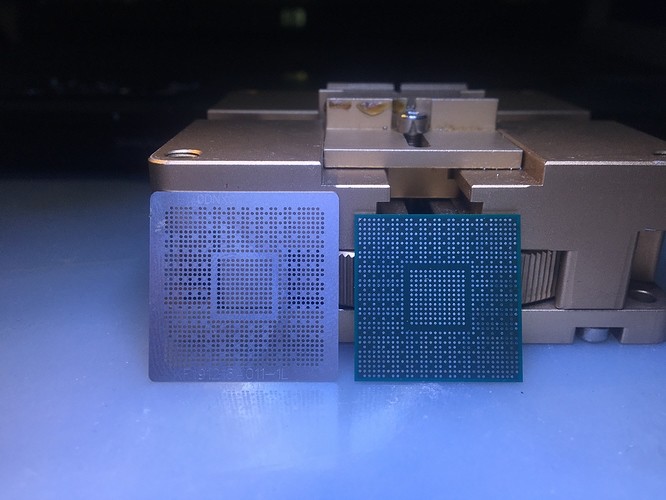

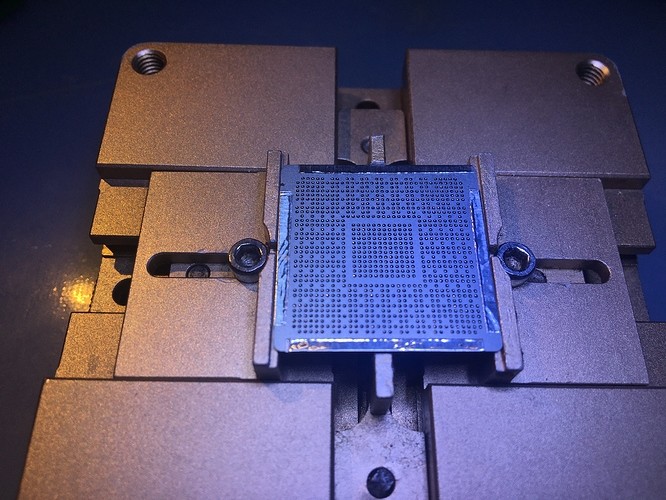

I used 0.35 balls

And you heat the solderballs direct with the stencil on the soc?

Is it possible to change the soc (with the emmc) to an other mainboard?

I have a mechanical damaged board beyond repair but I know the soc and its emmc are working fine.

Yes, heat the solderballs direct with the stencil on the SoC. Don’t put a lot of flux, to start “boiling” to raise your balls in stencil and the temperature somewhere around 320 degrees and air flow between 5 and 10%

I didn’t try to change the SoC, but it should work fine. It is paired only with eMMC

I found an interesting thread.

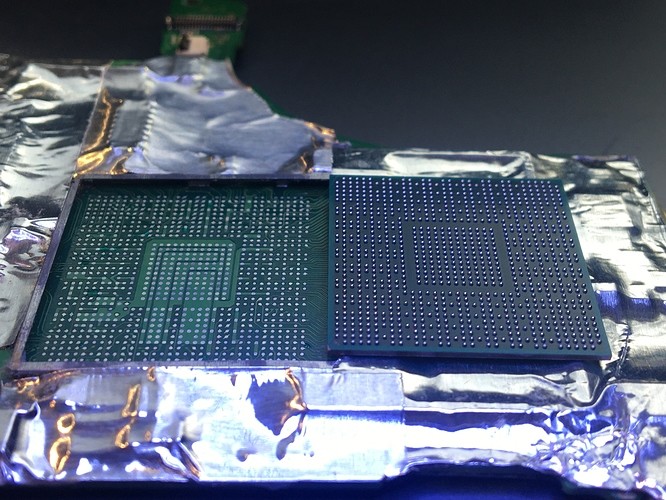

I tried to remove the SoC from the board, but failed due to pattern delamination.

I was told that too much heat would damage the SoC, but the time to apply the heat was too difficult.

From the back, I heated it at 250 degrees for 160 seconds, then injected flex into the SoC and heated it at 500 degrees from the SoC side.

Do you have any advice on how to avoid failure?

PREHEAT APU/CPU bottom area to 180celsius then apply hot air at the top side.

Your APU/CPU mostly dead when you desoldering out and resoldering back in your temperature profile

So to me it looks like your issue was less about having enough heat, but more about heat inconsistency, the pads pulled because you didn’t get the heat spread even enough by the looks of it.

This can happen when your using a slim nozzle on your hot air gun, or, you aren’t moving around enough, prior to lifing the SoC, you should check that the whole SoC is up to reflow temps by tapping the IC on the clear side, you should see the whole IC move, not just one or two corners, the corner where the pads have tore represents the highest mass so you’d want to make sure that moves also.

After, while still heating in a motion, use a vaccum pen to lift off the IC

Don’t worry man, you’ll get it, just takes practice ![]()

How to set a temperature of 500 degrees? It’s crazy … Tools do everything. It doesn’t come out with a cheap air station where you set 500 degrees and you put it to blow the air flow. Never. Use a dedicated reball station where you have a temperature control. Otherwise you will cry …