This is going to be a bit long but it’s worth covering as beginners tend to make the same mistakes when working on a board.

A few important points to remember - and I’l start with reflowing - is, the only time a reflow is going to resolve a problem is if one, the chip/components which are to be reflown have corrosion / liquid below them and by reflowing with flux your effectively “washing” it away (though more likely just lessening it) - for example, there is an IC which has a primary input rail at 5V and several ground pads, corrosion has caused a short or a partial short from the 5V line (or pads in this case) to the ground pads, thus preventing the chip from powering up due to the 5V line being pulled low.

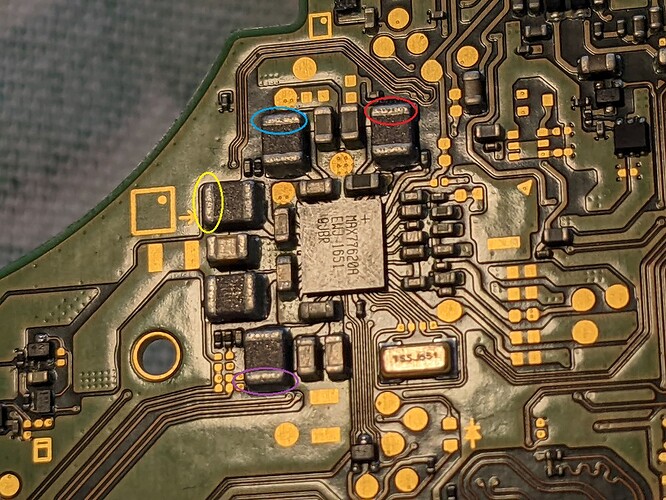

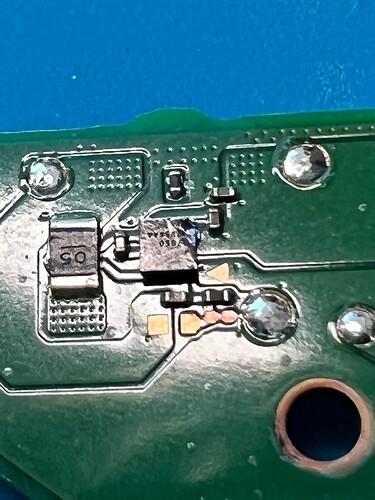

Second case for reflow would be joint failure which could be for one of two reasons - first being impact damage, in these instances we look out for clues of impact, in the case of Switch (and other handheld devices) you’d look at the outer & inner assembly for signs of impact damage, you’d also look at the board and see if there is any component damage, for example, bare die ICs (which are glass like) tend to fracture or chip, in extreme cases capacitors will shear clean off the board leaving very behind noticeable bare pads (often with the caps endcaps still attached). The second cause for joint failure would be board releated stress (and again this is more common on handheld devices) so you would again look at the main assembly and frame and check if there is any warp or twist, you’d also once again remove and take a close look at the board for any warp or twist too.

Now, in the first case of liquid or corrosion, you’ll have to use your better judgment here, if it’s extremely minimal corrosion you can sometimes make the determination that a “flux & boil” is enough to clean it out, sometimes that’s not enough and flux and reflow is the way but if the corrosion is too extreme or there is a suspicion of larger damage (below an IC for example) let’s say corrosion which has eaten through traces or corrosion which a reflow or flux and boil will not clean up enough then you might make the determination to remove the IC entirely to inspect (and reball/replace the IC if applicable)

So to summarise, you’d only ever reflow something if there was clear signs of corrosion/liquid, and you’d only attempt the reflow if the corrosion/liquid damage was minimal or more or less just superficial. In the case of suspected joint issues, you’d only ever reflow if there was clear signs of impact damage elsewhere, the gotcha here is, if the joint damage occured not as a result of drop/impact reasons but instead as a result of board related stress (maybe due to a bent frame, twisted etc) then it’s pretty unlikely a simple reflow will resolve, the reason being that what is most common in these cases to cause pad, VIA and trace level damage (usually below larger ICs) in these cases and when the reflow seemingly does resolve the issue, you’ll typically find the reflow only temporarily resolved the issue (for example trace damge on the mainboard below the SoC, heat has caused expansion/contraction and thus “moved” something, maybe reconnecting a line) This is why I say in instances where the board has clearly been stressed (bananna shaped boards for example) don’t torture the SoC with a reflow but instead either transfer the SoC and EMMC to another known good mainboard or go straight for SoC removal and inspect the PCB for VIA/trace issues (but again I wouldn’t suggest a beginner even goes down this road without extensive practice)

It’s also worth noting, even if there is clear signs impact elsewhere and the other symptoms align and a reflow is conducted, this doesn’t gurantee success, you still have to hope whatever ball which has potentially disconnected hasn’t fully sheared off and isn’t just floating around below, as if it is, no amount of reflowing will help.

Now in your case I see you went for the EMMC, I can tell you from my experience and reparing over 100 Switch consoles I thnk I’ve had maybe two cases where a BSOD was caused by an EMMC hardware related issue and maybe once where the BSOD was caused by EMMC data corruption. So I’m not saying that’s not your issue but rather just letting you know how likely/unlikely this is.

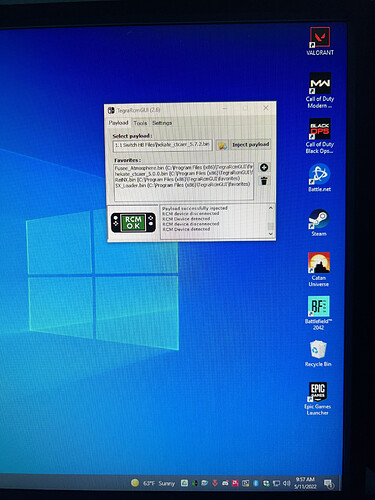

Next time, start with a less invasive method, check to see if the console is unpatched, if it is then (with a jig) boot up Hekate and verify if the EMMC can be read, if it can it’s highly unlikely to be an EMMC fault causing the BSOD. If it’s patched, then plug it in to your computer, if it’s detected as being in RCM mode it might be pointing to an EMMC ralted issue and you can move onto the next step. if it’s patched and it doesn’t show up in RCM state on PC then it’s less likely to be EMMC related (though this largely depends on other potential board faults)

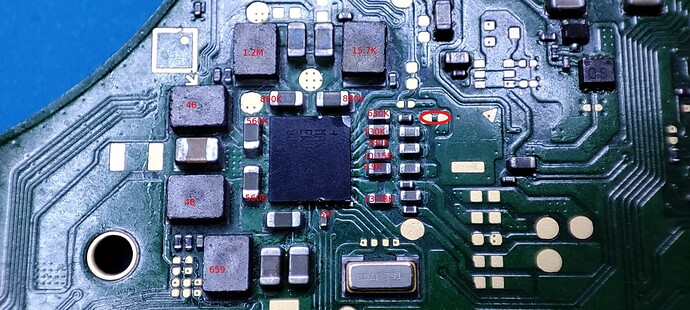

Working on the SoC is the absolute last resort, as I mentioned in the last topic of yours, BSOD is not just caused by the SoC, there is about 5 common reasons for it with the most likely being the fuel gauge, then ram then SoC and sometimes PMIC and sometimes EMMC related issues. The SoC is incredibly sensitive to heat, if your hot air gun is not up to the task all you will achieve is cooking it which tends to kill the low voltage rails in particular the CPU rails, this is because the die (the glass like section in the middle of the wafer) fractures internally in the process of abuse, a hard rigid material on a “soft” flexible wafer both materials expanding and contracting at different rates during heat up.

Good question, these are all things you should know the answer to before going down a reflow (and in particular the SoC reflow) route  answers which I (and others) have covered a bunch on this very forum

answers which I (and others) have covered a bunch on this very forum  by sifting through hundreds of topics you will learn other things in the process which will ultimately help you in the long run.

by sifting through hundreds of topics you will learn other things in the process which will ultimately help you in the long run.

Anyway hope that helps.

(If so, huge sigh of relief because i’m learning immensely.)

(If so, huge sigh of relief because i’m learning immensely.)