Hi all,

i would like to spend some time talking about soldering tip. I am having a hard time to find tip that i really feel comfortable to work with and would like to see your experience in this matter.

I have 2 soldering irons, one is a very “old school” Weller WS 50, with 2 LR21 hands, one “old version” and a “newer one” (i mean, one is using old “ET” and “MT” series and the other is using “LT” tip, with a “MT-LT” conversion unit in the hand).

I really like this soldering iron, it is solid, never gave me any sort of trouble, and the tip have a really good quality. However, the LR21 with the conversion “MT-LT” is not giving good result with super thin tip, the solder doesn’t hold at the edge of the tip and come a bit closer to the hand, which isn’t really practical when doing trying to work on QFN ic. For this reason i am trying to stick to the old tip series but they become hard to find and more expensive overall. And i tried other brand than original weller, it is a total disaster, sometimes it doesn’t even get warm enough to melt the solder.

On the other hand, i have also a Aoyue station that includes hot air gun and a soldering iron that uses the same tip as the Hakko T18 series. I would even consider in buying a handle from Hakko, they look much more solid than the equivalent from Aoyue (which i broke once pushing a bit too hard). The tip for that soldering iron are a nightmare. The only one that really works are the genuine Aoyue. Anything else i bought is useless. I would even consider to buy some Hakko to test, but in Europe it is really expensive, more than 10€ per tip (unless somone knows a good address).

That’s it, considering those 2 hardware, i would like to have your opinion on what / where / which tip you would recommend, making sure that when i tin the tip, the solder stays at the edge and doesn’t go to the hand leaving the edge “dry”.

Thanks.

Hi guys, not much activity over here  I do have a question anyway, hopefully i get some opinion, i have a possible deal to buy a soldering station Weller DS 701 EC, 220W 2 channels with desoldering pump for 100€. What do you think ? I know it is a vintage, but i have the feeling that for the price it can still do quite good stuff, WDYT about it ?

I do have a question anyway, hopefully i get some opinion, i have a possible deal to buy a soldering station Weller DS 701 EC, 220W 2 channels with desoldering pump for 100€. What do you think ? I know it is a vintage, but i have the feeling that for the price it can still do quite good stuff, WDYT about it ?

In regards to tips/stations I’d point you over to this topic here, over element style tips/irons are old fashioned and dated and offer marginal performance gains (if any) over those crappy direct plug into wall soldering irons

I have a modern desoldering pump / station and tbh I very rarely use it and in hindsight it was a waste of money, they’re only really useful if you were doing very large component removal on a daily basis, takes ages to heat up (compared to a T12 iron) and on anything > 2 layers (not old school boards) it struggles, the nozzle gets jammed constantly and you have to use the round files to unblock…mine sits there collecting dust and I find even on the stuff where it might be useful it’s easier, quicker and safer either just to use your soldering iron and levering the through-hole component out then using wick or just using wick from the off

I read your comments in this thread, but wasn’t able to come to an easy conclusion. But if i get it right and to make an easy point for me, you would more go to a station managing tip profiles and having T12 tips handle such as the Ksger from that topic or even the one you suggested reviewed by SDG, the JCID right ? Do we agree that the thinner tip of those soldering station holds good a drop of solder at the very edge of the tip right ? That’s basically my main concern with my current devices, no matter which one.

Well that would be my preference, as you’ll find you’ll graviate to a tip shape that you use 90% of the time and then another 5 tips (for example) for the remaining 10%, the tips will be close to each other in terms of “default” calibration compared to each other when new but over time they’ll all fall out of whack with each other, particularly yout 90% in use tip. So I find it’s really handy having the ability to use tip profiles with independent tip type calibration, which the KSGER offers… that being said, the KSGER T12 station will require some manual work to make it a decent station

If you wanted one that’s pretty much good to go out of the box then the AIXUN T3A might be a good choice, albeit with the downside you only have global tip calibration… I also notice (which I didn’t realise initially) their version of the T12 handle has a larger tip to grip distance with the T12 tip inserted vs the KSGER aluminium/SS handle… so if it were me, I’d probably buy the station with no handle then buythe KSGER Alu/SS handle and wire it up myself for a superior handle IMO, but I’m sure the default works fine worst case.

Like with any iron tip, it depends on the quality of the tips, if you were to get the cheapest clone Hakko T12 tips then they’re probably not going to behave perfectly vs decent quality clone T12 tips or genuine Hakko T12 tips.

I would say JBC tips in general (clone or real) hold the solder at the very tippy tip better initially vs T12 tips as a whole, but with a very neagative downside that the tips do not last nearly as long as the coating wears off, at which point it will refuse or stuggle to take any solder, and the other issue I noticed, on the finer tips, for example their JL02 shape equivelent, the coating at the very end which allows the solder to take was too small on the JBC tips, being atleast 1/3 the length/volume of an equivelent T12 tip, which effectively means 1/3 less the heat transfer… which basically invalidates the tips being almost twice the wattage ![]() bigger tips such as D24/D52 JBC equivelents that’s a different story but, I mean, if your irons is struggling with these large tips on any board, I think there is something seriously wrong regardless of tip “technology”

bigger tips such as D24/D52 JBC equivelents that’s a different story but, I mean, if your irons is struggling with these large tips on any board, I think there is something seriously wrong regardless of tip “technology”

Pfiou, many thanks for this amazing explanation @Severence really helpful. Just to make sure, when you say that the KSGER requires manual work to make it a decent station, are you referring to the fact that you need to calibrate each and every tip you are using with, or to something else ?

More that with the KSGER your going to have to open it up an ensure that the chassis is earthed and also that the earth is being passed through to the front panel PCB (to earth the tip) , Your also going to want to open up the T12 Alu/SS handle and remake the joints for the wiring and ditch the ball/mercury sleep switch (near useless)

You may find you want to upgrade the FW to the open source CFW with an ST-Link if the one which you order arrives with an inferior FW installed…though tbh I don’t think it’s that big a deal if it does, typically it just makes tip calibration a bit more finicky… but you have the option.

Tip calibration in general though is a once every 3/6 months occurrence, and typically your only going to be doing it on your most used tip, the process is relatively simple and once done it takes all but a second or two to switch to that tip profile in the menu

Just to add, there may well be a superior stations compared to the KSGER with all the above functionality I mentioned, you should look around before making the decision to order the KSGER

I see, i will review some SDG videos, but even on eevblog forum, i haven’t seen much choices then the KSGER and the Aixun T3A you suggested before. Will check and keep you posted thanks again

Very tricky decision, the KSGER as you lined out has a lot of things to be checked and tweaked, and in the end get the ability of calibrating each tip you want and is cheaper, even on the official Aliexpress store. On the other side, the T3A looks to be better manufactured, has a great handle, now a good stand as well, but lack the support of thermal calibration for each tip as of today, without knowing if this will be available with an update or a CFW in the future. I have the feeling that for what i want to do, and when i see with what hardware i was working so far, maybe i can live with the T3A which is kind of “plug and play” for me and hope independent tip calibration comes later…

Right, though with the caveat of their T12 handle having about 1/3 more tip stickout which is a shame.

As I mentioned though if you go with the T3A I’d opt for the T12…I like SDG but his opinion (and a lot of others) but his testing method is flawed, I think in part because of the difference in work we do

In case of i want to go with the KSGER, is that the handle you were recommending in the other thread, aluminum or stainless steel version ?

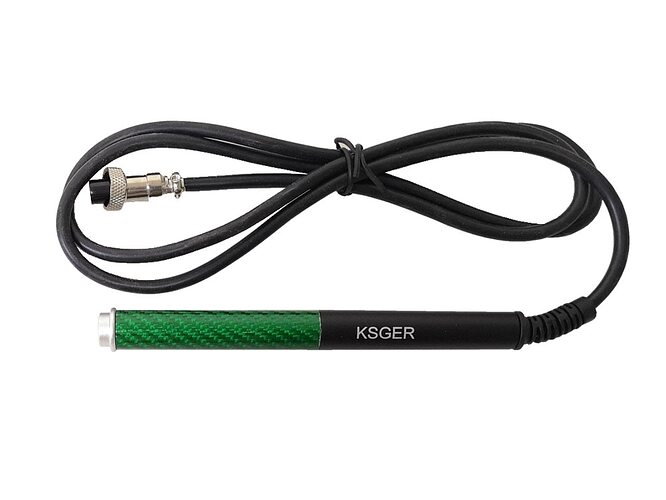

That one :

or that one

Yeah, my preference is the aluminium one in your second image, it feels more weighty and higher quality, is more ergonomic, though it can heat up to about 30C at the grip… this doesn’t bother me, but some people have trouble with this… so I guess if you have sensitive fingers go with the steel version or get some amalgamating tape to thicken the grip up on the aluminium one

Though as I mentioned earlier, they both use that terrible ball/mercury sleep switch internally which has to be ripped out, and the wiring needs properly soldered as the stock job isn’t great but it’s easy enough.

Also, the vast majority of KSGER boards support JBC handles with some modifications, this means you can effectively wire the aluminium handle chassis in the the same manner as a JBC and run a fly lead to the station so it sleeps when in a metal cradle… just a thought… haven’t done this myself yet on my one

I think you convinced me with this one

This was a feature that i liked on the T3A device. Modifying it isn’t really a blocker for me, and since it is cheaper than the T3A, i will still take 5min to think about it, but i do believe i took my decision. The green one is also aluminum body but to not have that warm grip they put that carbon fiber part around the internal body. Maybe that’s the best compromise ? I must be honest that i have sensitive fingers ![]()

I should note that the alumninium handle by default is not earthed (as its painted it’'s not really needed) so in order for the JBCsleep functionalityto be implemented you’d have to either crimp and thread the relevant conductor internally in the handle or simply solder the wire to the aluminium (don’t worry it’s basically room temp at the bottom end of the handle when the unit is on) but no big deal

You won’t be able to do this easily on the carbon fibre vairiant as the metal likely isn’t coupled from one end of the handle to the other… or you’d have to attach the wire to the metal ring at the very end which might be tricky for space constraint reasons

I’d probably still opt for the aluminium version and jut pick up a roll of amalgamating tape, a couple of wraps arund the grip will prevent sensitive finger syndrome

Ok, as said, will think about it and probably order by the end of the day i think. Yesterday again i fought with my 2 solder stations and the various tips i have to get the job done, and because the solder doesn’t stick to the end as said before is just a waste of time and energy. So i am really looking toward having these renewed and good tips to do the work. I read that KSGER are good tips to work with right ?

Haha, let’s see about that one then ![]()

Their tips are run of the mill, cheap defaults. though I’ve seen these tips be of varying quality and other sellers selling the tips but it’s obvious they were manufactured by a different company… but yeah in general they are fine for the money approx $3 a tip, can’t complain.

Thinking about it, these likely will fit on the alu handle

https://www.aliexpress.com/item/1005003239223476.html?spm=a2g0o.productlist.0.0.418051b4nyFtH3&algo_pvid=4d2805b7-4492-4a60-bcdd-29971a08deee&algo_exp_id=4d2805b7-4492-4a60-bcdd-29971a08deee-0&pdp_ext_f={"sku_id"%3A"12000024800180151"}&pdp_pi=-1%3B1.41%3B-1%3B115%40salePrice%3BGBP%3Bsearch-mainSearch

This is the same reason JBC use them on their handles… though I’m not a fan of them myself

Which one do you run and consider good one ?

When looking at the price, i can give it a try why not.

I found back when I started getting these T12 clone tips back when they started cropping up on Aliexpress that the quality was excellent and near 1:1 wth a legit Hakko tips… infact I still have about 20 tips from back then which are still more than usable. but in recent times it’s becoming a bit of a challenge to find a consistently good tip from one seller, I’ve ordered 3/4 tips from the same seller, same brand, and one in the batch might be bad or the coating wears off… What I can say for sure is don’t waste your money on the “black oxide” T12 tips… they are no different, and the moment you clean them in the brass sponge that fancy looking “black oxide” comes straight off

I’ve just ordered a whole bunch from Aliexpress to see if I can find a consistently good clone tip of decent quality… avoid “Maant” brand, they’re junk and arrive pre-bent and contrary to the listing images are the same as anyother clone T12 tip. I got a “Mechanic” branded T12 tip, and while I’m not a huge fan of this company as a lot of their products are usually junk, in this case, the tip looks decent quality… but I haven’t tested it yet in my handle so I’ll let you know when I get to it

I’ve also ordered one of these

I expect they will be a bit of a loose fit in the T12 handle as they’re lacking the crimp rings on the shaft but I’ll wrap a bit of kapton round in that area just for testing it out when it arrives

Alternatively, just buy a legit hacko tip of your most used tip type

Thanks, waiting also your feedback for the Mechanic one, maybe it will be a good surprise. From that brand, i at least find good enough the tweezer that i am using, the AAC-14. But that can also be because i don’t really know anything else

I got some of the Mechanic brand bue tweezers (don’t know if that’s the same as your version) and they’re junk, as the ends skew and don’t align from even the slightest sidewards pressure