One thing I did completely forget to mention, on the aluminium handle the internal silicone sleeve closest to the grip end is a very tight fit for a few months until it wears out a little, this can make it pretty hard to gauge if the tips are fully inserted to begin with. When the tips all the way home the scond crimp ring on the tips shaft should be just about insider the silicone ID, if your stuggling just put a bit of IPA on the tips shaft which will act as a temporary lubricant

So if your steel handle uses this same silicone sleeve on the ID you might want to check this.

btw that T3A station showed up the otherday, quality of the station itself seems excellent, got the flimsy stand instead of the bulky one which seems to work alright and supports the handle fine if a tips inserted otherwise without a tip it’s off balance and the handle will fall out. I opted for the T12 handle variant for the reasons mentioned previously

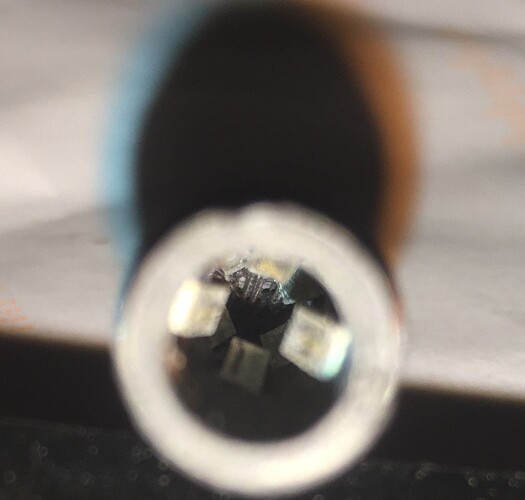

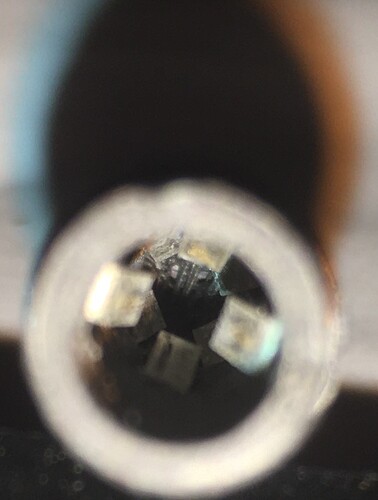

Handle quality seems nice, can’t tell if it’s steel or aluminium but the tip to grip ratio is really poor with almost twice the stickout compared to the KSGER handle/s (I’ll modify this by fitting a 3D extension piece in the middle if I can) They seem to be using PTFE/Teflon tubing on the ID closest to the grip instead of silicone which makes tip insertion somewhat easier but thiere is more play on the tip vs the silicone used in the Ksger version, the contact portion inside is the same crappy design with single contacts corresponding to each of the T12 tip contacts the same as what Hakko, Ksger, Quicko etc use and the terrible earth contact. Even though they have the fly lead (which is nice silicone cable btw) to go to the cradle for sleep sensing, they have installed the mercury “shake” switch inside their handle too… not really sure why they’ve done that unless it’s optional in the menu or something.

Anyway, I’ll plug it in at some point and give it a test but tbh I only bought it out of curiosity (and for a couple of other reasons) and can’t really see myself using it as my regular station without modifications of the installed FW

even without the PE connected to the negative. Not sure, will see with the CFW but i have the feeling it is hardware related.

even without the PE connected to the negative. Not sure, will see with the CFW but i have the feeling it is hardware related.