Hello everyone!

I’m new here, but I really need help with a faulty V2 Nintendo Switch I repaired, but somehow broke again. Let me tell you my tale of woe and… confusion:

(TL;DR: Repaired faulty V2 Switch, then installed HWFLY modchip which worked fine, but Switch needed to do an official firmware update to allow use of a Micro SD card. Update suddenly stopped modchip from working as it kept booting to OFW. Tried reflashing modchip several times, still wouldn’t work.

After opening back up to check soldering, removed modchip and Switch wouldn’t turn on. Replaced some capacitors on APU, but no joy. Can’t see any trace damage and can’t tell if anything is missing. Please help!!!)

So, I grabbed a faulty Switch off eBay which had the description of no power but good cosmetic condition. After assessing it, I saw that the USB C port was knackered. I’ve read a lot of posts and watched a lot of YouTube videos to know that this can cause all sorts of components to die. What’s worse is that someone else was inside this Switch before.

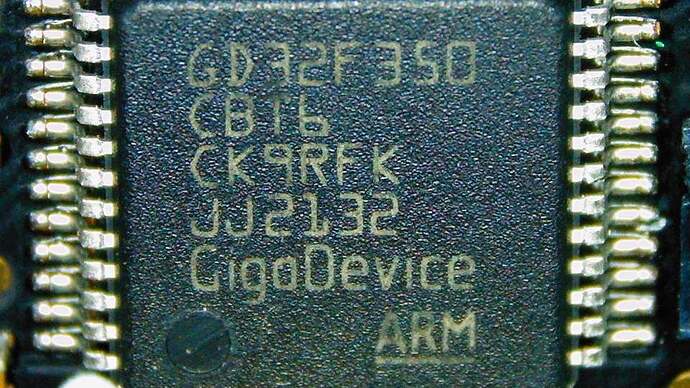

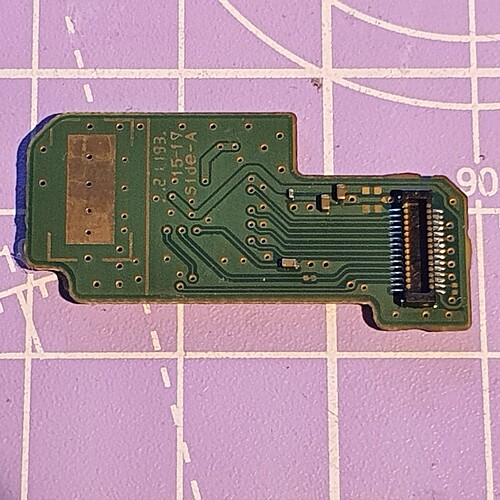

I replaced the following: M92T36, PI3USB30532ZLE, BQ24193 and MAX17050 as well as a few 0201 1uf capacitors. I picked up a donor board for extra parts and for the USB port as aftermarket ones didn’t seem to fit as good as a genuine one (sadly it was a V1 board which the seller pretty much lied about, but at least some parts were compatible) and did my best. I had to also repair a few traces around the PI3USB as well (annoyed me so much).

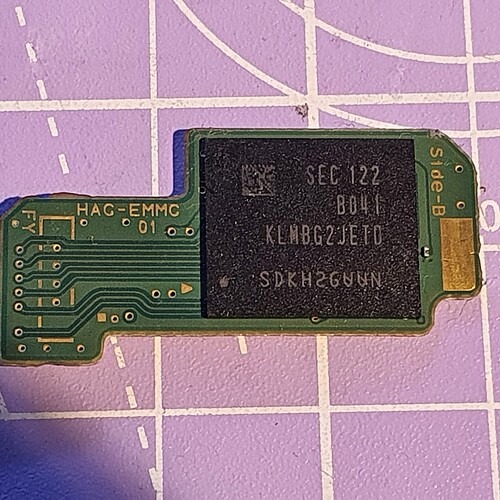

The battery was completely dead, so I picked up another (even the 9V battery trick that I’ve successfully used with overdischarged iPhone batteries didn’t work). IT SPRANG TO LIFE! It docked fine, charged fine with a genuine power adapter and I was so happy! Then I decided to do something stupid and install a HWFLY modchip. I was able to get it working on the first try (got that grey NO SD screen with the rocket that shoots with the power button)! Then things went downhill as I picked up a Nintendo licensed 128GB Micro SD card. The Switch have me a notice that it needed to update in order to up the card.

I thought “no problem” and let it do its thing. After a restart, I expected it to show the NO SD screen, but it booted straight into the original firmware? I kept trying to get the modchip to do its thing and no matter what buttons I held down, nothing worked. So I decided to try flashing the modchip. I learned that there was this one called “SPACESHIP NX” or something like that and used the one for my modchip. After finding a micro USB cable it liked I got it to be recognized by Windows and it flashed successfully. But the training lights kept going and going even after an hour and it was not as fast as it was when I first installed the modchip.

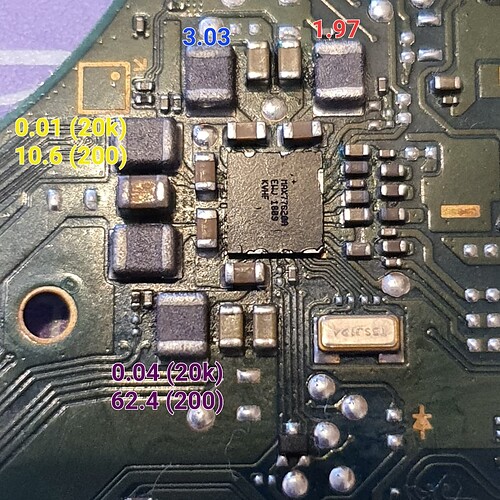

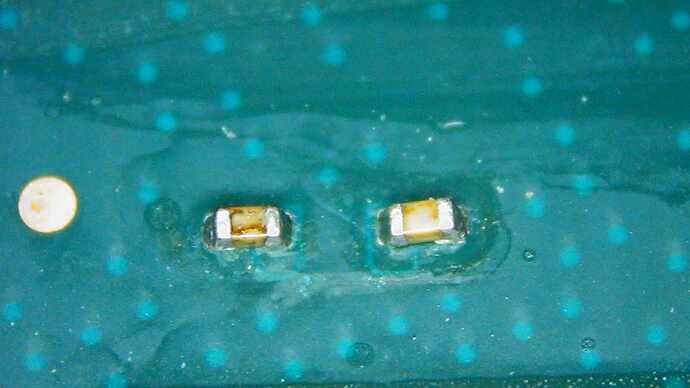

So I gave up and removed it thinking I could just sell the working Switch on for a good price. Now it won’t power up and I don’t know why! One of the capacitors looked a little iffy (SP1), so I replaced that with one from my donor board. Then I noticed that 4 of the capacitors on that row were shorted and I replaced them with donor and new 1uf capacitors. On Ohm mode (is that what it’s called? Anyway, I set it to 200k I think), with negative to the USB port as ground, all the ones I replaced now give a reading of 0.01. I have no idea what I did wrong and can’t see anything different, but I don’t have a clear picture of a working V2 board or even an idea what the correct readings should be.

I’ve tried reflowing the APU and then replaced the MAX77812 as I’ve read that it could cause a no boot if faulty (M92T36 seems fine as I get 15v when plugged into the genuine charger). Still nothing except when the battery is connected to the board you can hear a faint “whine” like something charging up? I’m so desperate to restore this back to the way it was and just sell it, hopefully to someone not as stupid as I am to mess with modchips off AliExpress. Can anyone help at all? I have about 26 photos which I’ll figure out how to upload so I can make my issue as clear as possible.

Hope to hear from anyone soon! Thank you for reading ALL of this if you did!